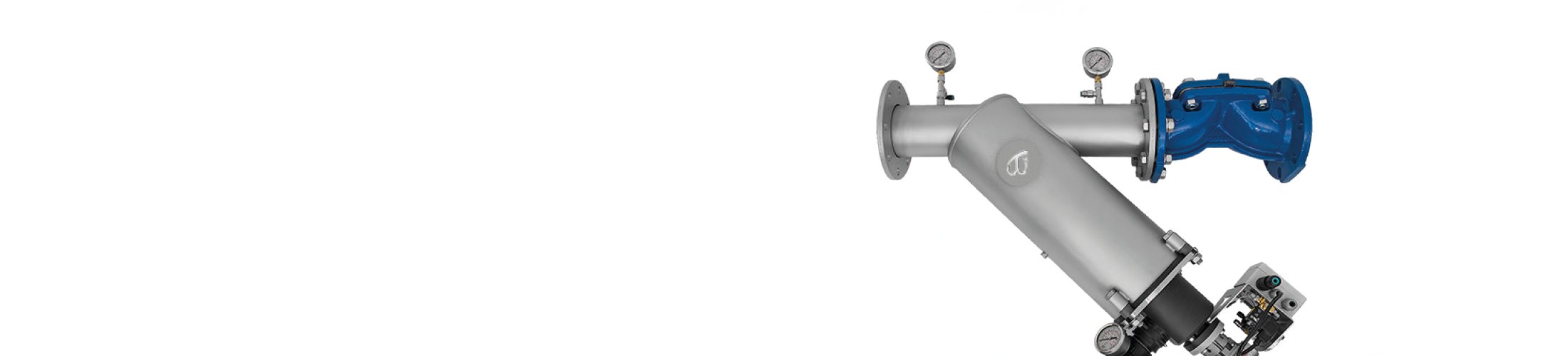

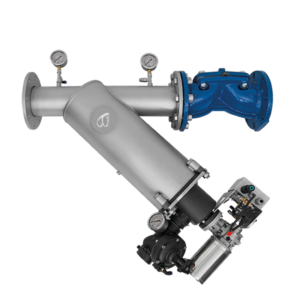

turbonet y

the smart choice for your goal

turbonet y

THE INTELLIGENT CHOICE FOR YOUR GOAL

Automatic cleaning filter with brushes for drinking and industrial water

There are various technological sectors where the filtration of significant quantities of water is required in order to remove suspended solids, coarse bodies and sand which could cause problems for hydraulic systems (valves, pumps, equipment). This need becomes particularly pressing when the sources of water supply are: rivers, lakes, canals, wells. In all these cases, the use of TURBONET Y series filters becomes the ideal solution. These are automatic filters equipped with differential pressure control capable of cleaning themselves independently thanks to rotating brushes and without the need to interrupt filtration. The main application sectors of the TURBONET Y series filters are: agriculture and irrigation, supply of evaporative towers, supplies of power plants for the production of hot water and steam, industrial applications in general. If there are significant quantities of sand in the water, TURBONET Y filters can be used as protection downstream of VORTEX series centrifugal separators.

TECHNICAL DATASHEET

In/out connections 2”

Drain connections 1” 1/2

Filtering area* m3/h 40

Area filtrante cm2 1500

Temperature of fluid to be treated min/max °C 5 - 60

Min/max working pressure bar 2,0 - 10

Pressure drop at nominal flow rate bar 0,2

Minimum cleaning cycle flow m3/h 5

Filter discharge flow rate L 18

Cleaning cycle time sec 6 - 15

Gaskets EPDM

Body and lid material AISI304

Support mesh material AISI316

Filter sock Poliestere o AISI316

Filtration degree μm Standard 120

Salinity and acidity < 10.000 ppm TDS, pH 3 ÷ 9

Power supply 230 Vac - 50/60 Hz

In/out connections 3”

Drain connections 1” 1/2

Filtering area* m3/h 80

Area filtrante cm2 1500

Temperature of fluid to be treated min/max °C 5 - 60

Min/max working pressure bar 2,0 - 10

Pressure drop at nominal flow rate bar 0,2

Minimum cleaning cycle flow m3/h 5

Filter discharge flow rate L 18

Cleaning cycle time sec 6 - 15

Gaskets EPDM

Body and lid material AISI304

Support mesh material AISI316

Filter sock Poliestere o AISI316

Filtration degree μm Standard 120

Salinity and acidity < 10.000 ppm TDS, pH 3 ÷ 9

Power supply 230 Vac - 50/60 Hz

In/out connections DN100

Drain connections 1” 1/2

Filtering area* m3/h 130

Area filtrante cm2 2200

Temperature of fluid to be treated min/max °C 5 - 60

Min/max working pressure bar 2,0 - 10

Pressure drop at nominal flow rate bar 0,2

Minimum cleaning cycle flow m3/h 7

Filter discharge flow rate L 25

Cleaning cycle time sec 6 - 15

Gaskets EPDM

Body and lid material AISI304

Support mesh material AISI316

Filter sock Poliestere o AISI316

Filtration degree μm Standard 120

Salinity and acidity < 10.000 ppm TDS, pH 3 ÷ 9

Power supply 230 Vac - 50/60 Hz

In/out connections DN100

Drain connections 1” 1/2

Filtering area* m3/h 140

Area filtrante cm2 3300

Temperature of fluid to be treated min/max °C 5 - 60

Min/max working pressure bar 2,0 - 10

Pressure drop at nominal flow rate bar 0,2

Minimum cleaning cycle flow m3/h 7

Filter discharge flow rate L 25

Cleaning cycle time sec 6 - 15

Gaskets EPDM

Body and lid material AISI304

Support mesh material AISI316

Filter sock Poliestere o AISI316

Filtration degree μm Standard 120

Salinity and acidity < 10.000 ppm TDS, pH 3 ÷ 9

Power supply 230 Vac - 50/60 Hz

In/out connections DN150

Drain connections 1” 1/2

Filtering area* m3/h 250

Area filtrante cm2 3300

Temperature of fluid to be treated min/max °C 5 - 60

Min/max working pressure bar 2,0 - 10

Pressure drop at nominal flow rate bar 0,2

Minimum cleaning cycle flow m3/h 7

Filter discharge flow rate L 25

Cleaning cycle time sec 6 - 15

Gaskets EPDM

Body and lid material AISI304

Support mesh material AISI316

Filter sock Poliestere o AISI316

Filtration degree μm Standard 120

Salinity and acidity < 10.000 ppm TDS, pH 3 ÷ 9

Power supply 230 Vac - 50/60 Hz

In/out connections DN150

Drain connections 1” 1/2

Filtering area* m3/h 300

Area filtrante cm2 5400

Temperature of fluid to be treated min/max °C 5 - 60

Min/max working pressure bar 2,0 - 10

Pressure drop at nominal flow rate bar 0,2

Minimum cleaning cycle flow m3/h 11

Filter discharge flow rate L 45

Cleaning cycle time sec 6 - 15

Gaskets EPDM

Body and lid material AISI304

Support mesh material AISI316

Filter sock Poliestere o AISI316

Filtration degree μm Standard 120

Salinity and acidity < 10.000 ppm TDS, pH 3 ÷ 9

Power supply 230 Vac - 50/60 Hz

Water Treatment Industry SRL

Via Molveno, 8

35035 Mestrino (PD) – ITALY

Tel. +39 049.9002505

info@wtindustry.com

Water Treatment Industry SRL

Via Molveno, 8

35035 Mestrino (PD) – ITALY

Tel. +39 049.9002505

info@wtindustry.com