WTI-300

THE SMART CHOICE FOR YOUR GOAL

WTI-300

THE SMART CHOICE FOR YOUR GOAL

Iron and manganese removal filters for potable and industrial water

![]()

The WTI-300 iron and manganese removal filters contain a mixture of quartzite and pyrolusite, a specific manganese oxide that acts as a catalyst for the oxidation of iron and manganese, leveraging the action of an oxidizing agent added to the water (sodium hypochlorite). The catalytic process takes place on the surface of the granule, leading to the formation of a floc that is mechanically retained by the quartzite in the filter bed itself. During operation, there will be a gradual clogging of the filter bed, resulting in an increase in pressure losses. It becomes necessary to periodically perform backwashing, an operation that sends water in countercurrent through the filter bed, removing accumulated solids and restoring the original filtration capacity.

The WTI-300 iron and manganese removal filters are specially designed and manufactured pressure rapid filters for reducing iron and manganese in well and groundwater. The WTI-300 filters are suitable for treating water intended for human consumption, technological use, or industrial processes.

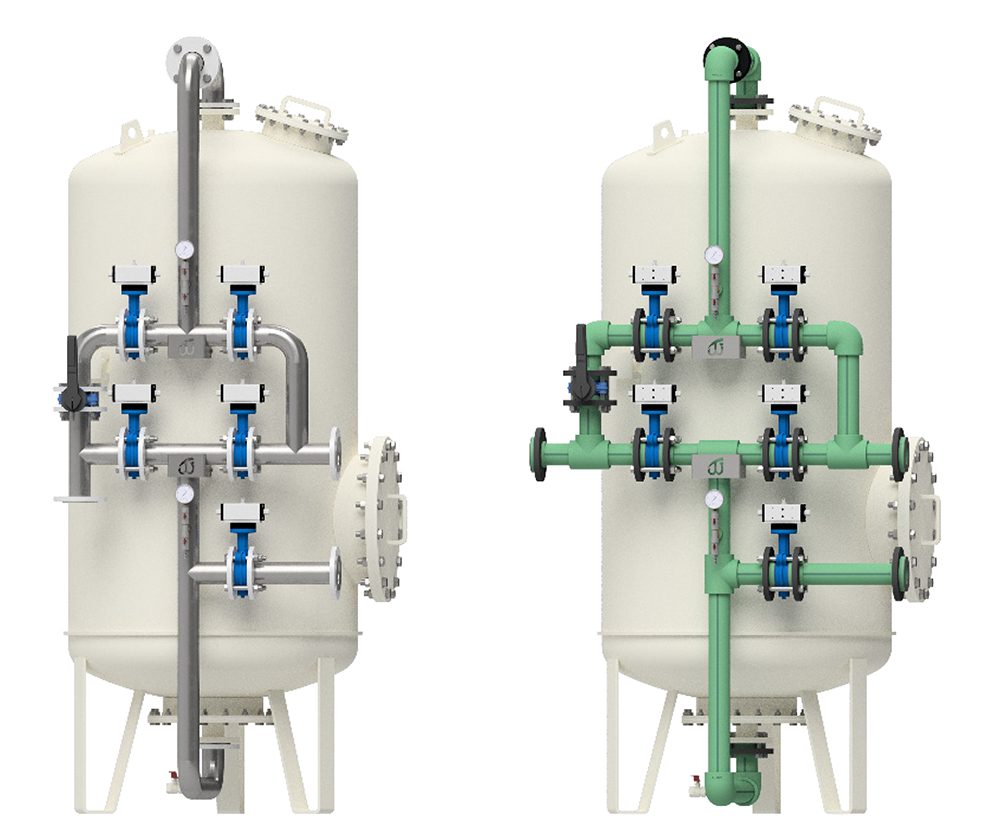

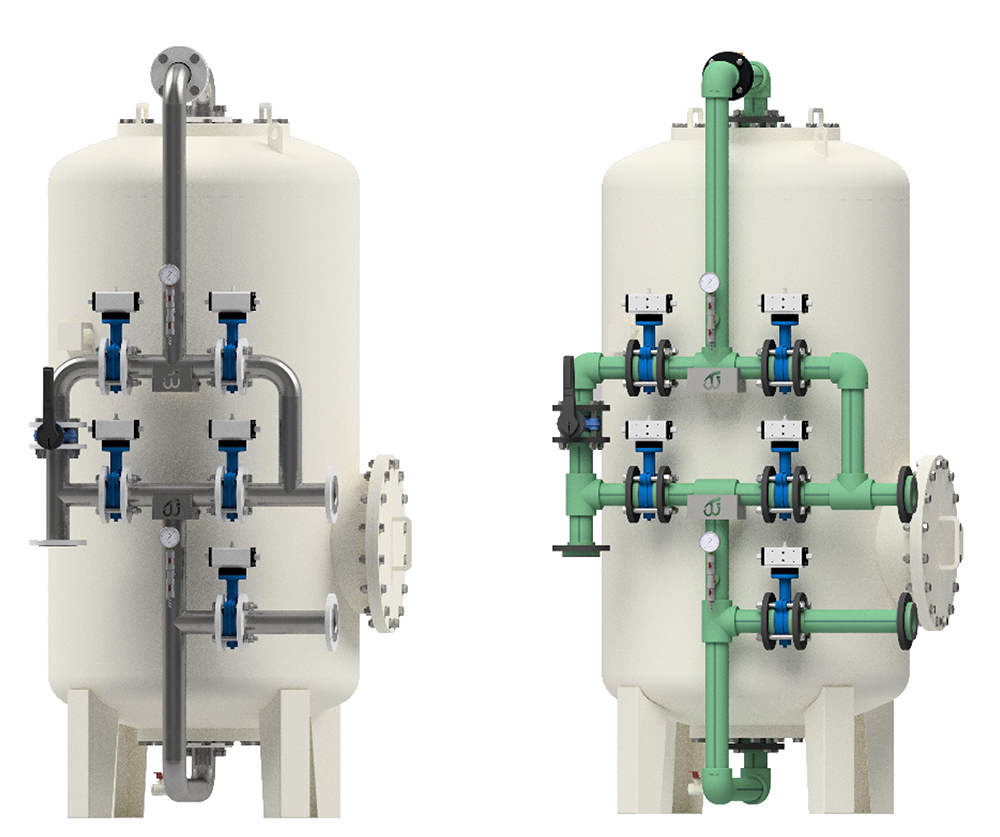

The WTI-300 iron and manganese removal filters are available in STANDARD and LUNA models (both can be constructed with stainless steel or polypropylene pipes). The LUNA models have the advantage of a lower height for the same diameter, thanks to the integrated manhole with the pipe inlet. Each model and execution are available in manual (up to 1200 mm diameter) and automatic versions (with pneumatic valves).

TECHNICAL DATA SHEETS

Fittings IN/OUT DN 40

Operating flow* m3/h 2.2

Maximum flow** m3/h 3.5

Backwash water flow m3/h 5.0

Technical datasheet

currently being updated

Fittings IN/OUT DN 40

Operating flow* m3/h 3.2

Maximum flow** m3/h 5,0

Backwash water flow m3/h 6,7

Technical datasheet

currently being updated

strong>Fittings IN/OUT DN 50

Operating flow* m3/h 5,0

Maximum flow** m3/h 7,5

Backwash water flow m3/h 10,0

Technical datasheet

currently being updated

Fittings IN/OUT DN 65

Operating flow* m3/h 8,0

Maximum flow** m3/h 11,8

Backwash water flow m3/h 15,7

Technical datasheet

currently being updated

Fittings IN/OUT DN 65

Operating flow* m3/h 11,0

Maximum flow** m3/h 17,0

Backwash water flow m3/h 22,6

Technical datasheet

currently being updated

Fittings IN/OUT DN 80

Operating flow* m3/h 15,0

Maximum flow** m3/h 23,0

Backwash water flow m3/h 30,8

Technical datasheet

currently being updated

Fittings IN/OUT DN 100

Operating flow* m3/h 20,0

Maximum flow** m3/h 30,0

Backwash water flow m3/h 40,2

Technical datasheet

currently being updated

Fittings IN/OUT DN 125

Operating flow* m3/h 25,0

Maximum flow** m3/h 38,0

Backwash water flow m3/h 51,0

Technical datasheet

currently being updated

Water Treatment Industry SRL

Via Molveno, 8

35035 Mestrino (PD) – ITALY

Tel. +39 049.9002505

info@wtindustry.com

Water Treatment Industry SRL

Via Molveno, 8

35035 Mestrino (PD) – ITALY

Tel. +39 049.9002505

info@wtindustry.com