vacuum y

THE SMART CHOICE FOR YOUR GOAL

vacuum y

THE INTELLIGENT CHOICE FOR YOUR GOAL

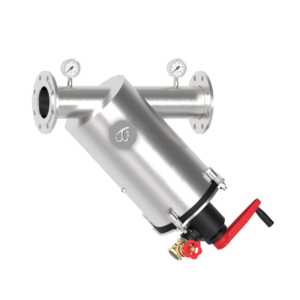

Manual cleaning filter with suction pads for drinking and industrial water

There are various technological sectors where the filtration of significant quantities of water is required in order to remove suspended solids, including those of a colloidal nature (silt, sand, etc.) which could cause problems for hydraulic systems (valves, pumps, equipment). This need becomes particularly pressing when the sources of water supply are: rivers, lakes, canals, wells. In all these cases, the use of filters from the VACUUM Y series becomes the ideal solution. VACUUM Y filters are Y-shaped filters with filter cartridge and mechanism with special suction pads which guarantee effective cleaning of the filter element with reduced water consumption and without flow interruption. The water to be treated feeds the filter through the inlet connection, passes through the filter element from the inside to the outside and flows to the outlet connection. Suspended solids and silt remain retained in the internal part of the filter element. During the filtration phase the drain connection remains closed.

TECHNICAL DATASHEET

In/out connections 2”

Drain connections 1” 1/2

Maximum flow rate m3/h 30

Filtering area cm2 1500

Temperature of fluid to be treated min/max °C 5 - 60

Operating pressure min/max bar 2,0 - 10

Pressure drop at nominal flow rate bar 0,2

Minimum cleaning cycle flow m3/h 6

Filter discharge flow rate L 15

Cleaning cycle time sec 8 - 16

Gaskets EPDM

Body and lid material AISI304

Support mesh material AISI316

Filter sock Poliestere o AISI316

Filtration degree μm Standard 120

Salinity and acidity < 10.000 ppm TDS, pH 3 ÷ 9

Technical datasheet

currently being updated

In/out connections 3”

Drain connections 1” 1/2

Maximum flow rate m3/h 80

Filtering area cm2 1500

Temperature of fluid to be treated min/max °C 5 - 60

Operating pressure min/max bar 2,0 - 10

Pressure drop at nominal flow rate bar 0,2

Minimum cleaning cycle flow m3/h 6

Filter discharge flow rate L 15

Cleaning cycle time sec 8 - 16

Gaskets EPDM

Body and lid material AISI304

Support mesh material AISI316

Filter sock Poliestere o AISI316

Filtration degree μm Standard 120

Salinity and acidity < 10.000 ppm TDS, pH 3 ÷ 9

Technical datasheet

currently being updated

In/out connections DN100

Drain connections 1” 1/2

Maximum flow rate m3/h 130

Filtering area cm2 2200

Temperature of fluid to be treated min/max °C 5 - 60

Operating pressure min/max bar 2,0 - 10

Pressure drop at nominal flow rate bar 0,2

Minimum cleaning cycle flow m3/h 9

Filter discharge flow rate L 25

Cleaning cycle time sec 8 - 16

Gaskets EPDM

Body and lid material AISI304

Support mesh material AISI316

Filter sock Poliestere o AISI316

Filtration degree μm Standard 120

Salinity and acidity < 10.000 ppm TDS, pH 3 ÷ 9

Technical datasheet

currently being updated

In/out connections DN100

Drain connections 1” 1/2

Maximum flow rate m3/h 140

Filtering area cm2 3300

Temperature of fluid to be treated min/max °C 5 - 60

Operating pressure min/max bar 2,0 - 10

Pressure drop at nominal flow rate bar 0,2

Minimum cleaning cycle flow m3/h 9

Filter discharge flow rate L 25

Cleaning cycle time sec 8 - 16

Gaskets EPDM

Body and lid material AISI304

Support mesh material AISI316

Filter sock Poliestere o AISI316

Filtration degree μm Standard 120

Salinity and acidity < 10.000 ppm TDS, pH 3 ÷ 9

Technical datasheet

currently being updated

In/out connections DN150

Drain connections 1” 1/2

Maximum flow rate m3/h 250

Filtering area cm2 3000

Temperature of fluid to be treated min/max °C 5 - 60

Operating pressure min/max bar 2,0 - 10

Pressure drop at nominal flow rate bar 0,2

Minimum cleaning cycle flow m3/h 9

Filter discharge flow rate L 25

Cleaning cycle time sec 8 - 16

Gaskets EPDM

Body and lid material AISI304

Support mesh material AISI316

Filter sock Poliestere o AISI316

Filtration degree μm Standard 120

Salinity and acidity < 10.000 ppm TDS, pH 3 ÷ 9

Technical datasheet

currently being updated

In/out connections DN150

Drain connections 1” 1/2

Maximum flow rate m3/h 300

Filtering area cm2 5400

Temperature of fluid to be treated min/max °C 5 - 60

Operating pressure min/max bar 2,0 - 10

Pressure drop at nominal flow rate bar 0,2

Minimum cleaning cycle flow m3/h 15

Filter discharge flow rate L 66

Cleaning cycle time sec 8 - 16

Gaskets EPDM

Body and lid material AISI304

Support mesh material AISI316

Filter sock Poliestere o AISI316

Filtration degree μm Standard 120

Salinity and acidity < 10.000 ppm TDS, pH 3 ÷ 9

Technical datasheet

currently being updated

Water Treatment Industry SRL

Via Molveno, 8

35035 Mestrino (PD) – ITALY

Tel. +39 049.9002505

info@wtindustry.com

Water Treatment Industry SRL

Via Molveno, 8

35035 Mestrino (PD) – ITALY

Tel. +39 049.9002505

info@wtindustry.com